US agency ends investigation into Ford engine failures after recall...

페이지 정보

본문

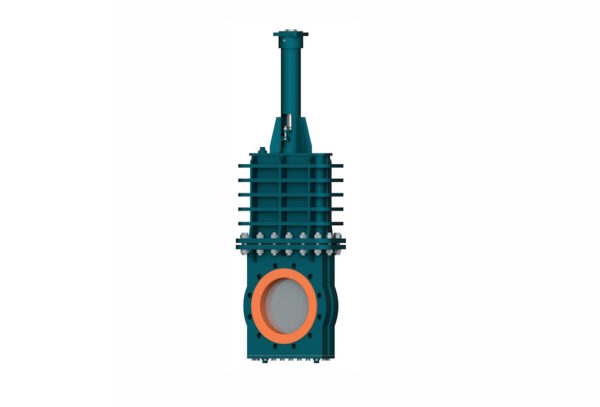

The fitting should be made of materials resistant to aggressive influences of petroleum products and the environment. Strength and durability. The design should withstand high pressures and temperatures typical for the transportation of petroleum products. Tightness: The tightness class. The fitting must meet high tightness standards to prevent environmental leaks and pollution. Tests and certification. Each product must undergo strict tests for tightness and strength before commissioning.

Maintenance and repair: Regular maintenance. Installation of monitoring and monitoring systems of the state of reinforcement allows you to timely detect malfunctions and prevent accidents. Compliance with standards: International and national standards. Materials and construction: Corrosion resistance. The presence of spare parts and repair kits should be provided for the prompt restoration of the displacement of the valve. Safety of operation: Instructions and Адмірал - завод трубопровідної запорної арматури (admiralzavod.ua.market) training.

It is necessary to carry out scheduled inspections and maintenance of reinforcement to prevent wear and failure. Availability of spare parts. It is important to take into account environmental requirements and standards to minimize the negative impact on the environment. The fitting must meet the standards, such as API, ANSI, GOST, which guarantees its quality and reliability. Environmental norms. The staff must be trained in the proper operation of the fittings and actions in emergency situations.

Monitoring system. In the process of operation of the latches, elements such as sealing and spindle play an important role. Latches are one of the main types of shut-off valves used in pipeline systems to completely cover the flow of the working medium. Understanding the differences between the retractable and non-retractable spindle, as well as the features of the seal, allows you to choose and effectively use the latches in different conditions.

Latch seal Use secondary containment with a sensor My recommendation is to leave the gasket alone for the reasons mentioned by the operations department. I would add a jacket around the flange and a sensor to detect if there is any leakage. The signal should be transmitted to the control room and to a traffic light located at the bridge that signaled if travel on the bridge was safe or not. The jacket would provide a small amount of secondary containment but would also concentrate any vapors so that the leak can be detected more readily.

Since the flange has not leaked to date is a good reason to leave it alone but it does not insure that a leak won't develop in the future. A variety of types of fittings and strict requirements for its operation allow to minimize the risks of accidents and leaks, ensuring reliable operation of the entire system.

Since the flange has not leaked to date is a good reason to leave it alone but it does not insure that a leak won't develop in the future. A variety of types of fittings and strict requirements for its operation allow to minimize the risks of accidents and leaks, ensuring reliable operation of the entire system.

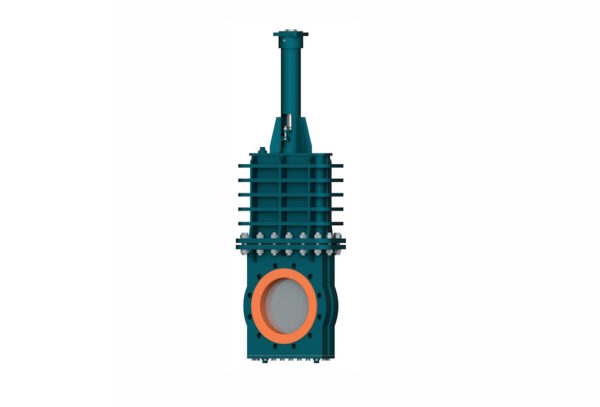

Maintenance and repair: Regular maintenance. Installation of monitoring and monitoring systems of the state of reinforcement allows you to timely detect malfunctions and prevent accidents. Compliance with standards: International and national standards. Materials and construction: Corrosion resistance. The presence of spare parts and repair kits should be provided for the prompt restoration of the displacement of the valve. Safety of operation: Instructions and Адмірал - завод трубопровідної запорної арматури (admiralzavod.ua.market) training.

It is necessary to carry out scheduled inspections and maintenance of reinforcement to prevent wear and failure. Availability of spare parts. It is important to take into account environmental requirements and standards to minimize the negative impact on the environment. The fitting must meet the standards, such as API, ANSI, GOST, which guarantees its quality and reliability. Environmental norms. The staff must be trained in the proper operation of the fittings and actions in emergency situations.

Monitoring system. In the process of operation of the latches, elements such as sealing and spindle play an important role. Latches are one of the main types of shut-off valves used in pipeline systems to completely cover the flow of the working medium. Understanding the differences between the retractable and non-retractable spindle, as well as the features of the seal, allows you to choose and effectively use the latches in different conditions.

Latch seal Use secondary containment with a sensor My recommendation is to leave the gasket alone for the reasons mentioned by the operations department. I would add a jacket around the flange and a sensor to detect if there is any leakage. The signal should be transmitted to the control room and to a traffic light located at the bridge that signaled if travel on the bridge was safe or not. The jacket would provide a small amount of secondary containment but would also concentrate any vapors so that the leak can be detected more readily.

Since the flange has not leaked to date is a good reason to leave it alone but it does not insure that a leak won't develop in the future. A variety of types of fittings and strict requirements for its operation allow to minimize the risks of accidents and leaks, ensuring reliable operation of the entire system.

Since the flange has not leaked to date is a good reason to leave it alone but it does not insure that a leak won't develop in the future. A variety of types of fittings and strict requirements for its operation allow to minimize the risks of accidents and leaks, ensuring reliable operation of the entire system.- 이전글11 Creative Methods To Write About Best Refrigerator Brand 25.02.19

- 다음글15 Top Twitter Accounts To Discover Link Login Gotogel 25.02.19

댓글목록

등록된 댓글이 없습니다.